Description

Epoxy based self levelling flooring system that is of 2 -3 component, hygienic, easy to clean and maintain, dust free, smooth surface, antiskid, coloured nature.

Characteristics

- Resistant to chemical and mechanical abrasion

- Antiskid surface

- Easy to apply

- Very high adhesion strength

- Non-solvent

- High chemical and mechanical strength

Areas of Use

- Control Rooms

- Chemistry and medicine industry

- Food and beverage industry

- Sterile rooms, laboratories and hospitals

- Nuclear energy plants

- Storerooms

- Thermal and hydroelectric power plants

Epoxy Self Levelling is a non-jointed flooring type that makes worn, hollowed, damaged concrete floor surfaces bright, dense and smooth. With this chemical based coating, floors can be formed in a fast and durable manner. After the application, the flooring becomes suitable for walking over within 6 to 8 hours. Working with this floor improvement method may prevent the losses brought by work period problems. Epoxy flooring is a fast method. Easy to clean and bright surfaces can be formed.

Epoxy flooring can be used with different colour preferences in electricity plants, machinery factories, food production factories, medicine factories, hospitals, chemical factories, tobacco factories, textile factories, clothing workshops, furniture industry, plastic manufacturing plants, stations and sports complexes.

Epoxy Flooring Characteristics

- Dust free, corrosion free, watertight

- Resistant to friction and abrasion

- Easy to clean

- Fast and easy to apply

- Easy and economical maintenance and repair

- High adhesive quality and elasticity

- Resistant to impact

- Thickness between 0.2 mm - 0.5 mm

Description

Bright, self levelling flooring with 2 components, epoxy based, non-solvent, high abrasion and chemical resistance, hygienic, easy to clean, antistatic (transferring static electricity to the ground).

Characteristics

- Resistant to chemical and mechanical abrasion

- Easy to apply

- Very high adhesive strength

- Non-solvent

- High mechanical and chemical strength

Areas of Use

Surgery rooms, computer rooms etc. electronic equipment areas.

This is a floor coating type used frequently in sports halls and industrial floors that can be applied in one piece, without joints or junctions. It is dust free and easily cleaned. Bright and coloured surfaces may be formed. This is a flooring that does not accumulate dust and dust on it is easy to clean. Applied for both interior and exterior surfaces, this flooring type is resistant to sunlight. It does not become matte, and is resistant to deformations such as cracking and drying abrasion.

The application surface should be dry and clean. Dirty surfaces should be cleaned via vacuum air or lukewarm water. Floor surface should be completely dry. After the surface is made ready, flooring application may begin. Coating process may be conducted by spraying method or laying methods.

After the application, the tools used are washed with a special mixture. Because the coating is prepared from chemical components; in case of contact with hand or other part of body, it should be cleaned with water or alcohol.

Areas of Use

- Aesthetic, hygienic, antiskid, quickly cleaned, in sports (basketball, handball etc.) areas

- In places where visual effect from colour variation is sought for, around swimming pools

- This dust free flooring type is also useful for noise insulation

- With colour differences used on the floor, dust accumulating places can be controlled

- Decorative and resistant, low maintenance requirement, can be used in sports, industrial et. areas

Advantages

- Can be applied via spraying or readily laying on the floor

- Highly resistant to abrasion, elasticity and antiskid surfaces

- Resistant to ultraviolet rays, does not crack or become matte

- Can resist temperatures up to 90 C and down to - 30 C

- Does not move from place after coated

- Can be used either inside or outside the structures

- Dust free flooring

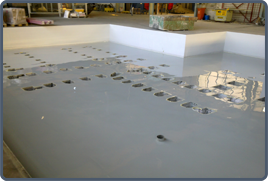

This is a strong and durable floor material that can be used in factories, shopping centres, storehouse, stations, car park and similar places where there is dense pedestrian and vehicle traffic. It is dust free and easy to clean. The material is resistant to chemical effects, abrasion and mechanical effects. Patterned, rough and semi-matte surfaces may be formed.

Surface subject to coating should be dry and clean. For the surface to be suitable for application, it should be lightly rough. Dirty surfaces should be cleaned via vacuum air or lukewarm water. Floor surface should be completely dry. Cracks and gaps should be repaired with suitable structure chemicals. After the surface is made ready, flooring application may begin. These floor coatings applied as a mixture on the surface by smearing take their last form through a chemical reaction. It has allergic effects. All kinds of protective measures should be taken during application. The mixture is mixed until it reaches an adequate consistency. Afterwards, the mixture is smeared onto the surface via trowel without leaving any joint section or marks, completing the flooring application.

Characteristics

- May be applied without joints and junction sections

- Visual effect can be created

- Dust free, easy to clean

- Hygienic

- Resistant to abrasion and impacts

- Resistant to chemical effects

- Thickness between 2mm - 3mm

Description

Cold application road paint used with convenience in interior environments, with an epoxy based, double component nature

Areas of Use

Conveniently used on epoxy, concrete, surface hardener, mosaic etc. surfaces. Line, arrow, pedestrian crossing, letter and number applications are easily done.

Main Fields of Use

- Industrial areas, manufacturing plants and storehouses

- Airports and shipyards

- Military areas

- Car parks

- Residential sites

- Shopping centres.

Characteristics

- Cold application road marking paint

- Manufactured in traffic paint colours compliant to RAL standards

- Resistant to dirt, grease, dust etc. conditions and effects

Description

Epoxy based, hygienic, easy to maintain, dust free, coloured flooring system with 2 -3 components.

Areas of Use

- Control Rooms

- Production and Storage areas

- Accumulator-Charging Rooms

- Sterile rooms, laboratories and hospitals

- Chemical washing and machinery floors

- Nuclear energy plants

Characteristics

- Resistant to chemical and moderate mechanical abrasion effects

- High adhesive strength

- Hygienic and easy to clean

Description

Double component, hygienic, easy to clean and maintain, dust free, smooth surfaced, antiskid, coloured, epoxy industrial mortar flooring system.

Areas of Use

- Control Rooms

- Chemical and medicine industry

- Showrooms

- Heavy metal processing and stocking areas

- Service stations

- Thermal and hydroelectric power plants

Characteristics

- Highly resistant to chemical and mechanical abrasion

- Very high adhesion strength

- Non-solvent

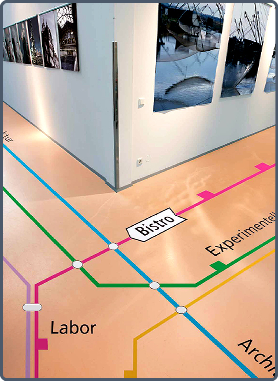

With flooring oriented Epoxy and Polyurethane systems, it is possible to create solutions with the design power desired regarding architectural creativity with limitless colour and decoration freedom.

With flooring oriented Epoxy and Polyurethane systems, it is possible to create solutions with the design power desired regarding architectural creativity with limitless colour and decoration freedom.

Granule Systems, with the application of mixture including marble, quartz, granite, glass or other suitable aggregate by preparing with special cement or epoxy binder.

Epotek Art Systems that can transform your floor to a work of art with its aesthetical appearance

Areas of Use

- Hotels

- Shopping Centres

- Supermarkets

- Airports

- Exhibition and Exposition Halls

- Education Institutions

- Restaurants

- Residential and Social Facilities